To beat brake rub forever, you can do a simple, 7-minute fix yourself. Start by inspecting and cleaning your brake pads, rotors, and calipers to remove rust, debris, and uneven wear. Properly align and adjust these parts, then test drive to ensure noise-free stopping. Avoid common mistakes like neglecting brake fluid or rushing the process. If you want to discover all the steps and tips, keep going—this quick fix really functions.

Key Takeaways

- Regularly inspect brake components for uneven wear, dirt buildup, and rust to prevent rubbing issues.

- Use a wire brush and brake cleaner to remove rust and debris from rotors and calipers in minutes.

- Ensure brake pads are properly aligned and replace worn pads promptly to avoid squealing and rubbing.

- Check and top off brake fluid, and verify caliper piston movement to maintain proper brake function.

- Follow a quick 7-minute procedure: lift vehicle, clean rotors, check pad alignment, and test drive for smooth braking.

Why Brake Squeal and Rubbing Happen and How They Affect Your Car

Brake squeal and rubbing occur when the brake components don’t work smoothly together, often due to worn pads, dirt buildup, or misaligned parts. One common brake noise cause is improper caliper alignment, which can cause uneven pressure on the pads and rotors. When the caliper isn’t aligned properly, it creates friction that leads to squealing or rubbing sounds whenever you brake. Worn brake pads can also cause noise because they no longer grip evenly, increasing vibrations and squeals. Dirt and debris trapped in the brake system can exacerbate these issues, causing additional noise and uneven wear. Recognizing these causes helps you understand how misalignment and brake wear impact your vehicle’s performance, emphasizing the importance of timely inspections and adjustments to keep your brakes quiet and effective. Additionally, incorporating innovative European cloud servers can support your vehicle diagnostics and maintenance data management for more efficient service. Regular inspections can help identify wear patterns early, preventing more severe damage and noise issues, and understanding brake system dynamics can further improve maintenance outcomes. Paying attention to noise symptoms can also alert you to underlying problems before they worsen, and staying informed about regulatory standards can ensure your brakes remain compliant with safety requirements.

Gathering Tools and Following Safety Tips for a Quick Brake Fix

Before you start fixing your brakes, gather all the essential tools on your checklist to work efficiently. Make sure you understand and follow safety precautions to prevent accidents or injuries. Being prepared and cautious helps you complete the repair quickly and safely. Additionally, understanding professional email etiquette can help you communicate effectively with others if you need assistance or share updates during your repair process. Incorporating smart home automation principles can also help monitor your vehicle’s maintenance needs remotely, enhancing overall safety and convenience. Recognizing the importance of proper lighting when working on your vehicle can prevent mistakes and improve visibility, reducing the risk of injury. Using risk assessment techniques before starting work can help identify potential hazards and plan accordingly. Remember, water safety measures are crucial even when working around water or in environments that involve water-related tools and equipment.

Essential Tools Checklist

To guarantee a smooth and safe brake repair, start by gathering the essential tools you’ll need. Having the right equipment makes addressing brake noise or pad replacement quick and efficient. Make certain you have a reliable jack and jack stands to lift the vehicle safely. A set of socket wrenches will help remove and reinstall calipers and rotors with ease. Don’t forget a brake cleaner spray to eliminate dust and grease, assuring a clean surface for pad replacement. Additionally, a rubber mallet can help dislodge stubborn components without damage. Using proper tools can also help prevent damage to delicate brake components. These tools streamline the process, reduce frustration, and help you complete the fix in just minutes. Proper tools also minimize risks, keeping you safe while working on your brake system. Knowing how to use tools correctly ensures safety and effectiveness during your repair. Remember to wear safety gear such as gloves and eye protection to prevent injuries while working. It’s also helpful to have a torch or flashlight for better visibility in tight or poorly lit areas. Additionally, consulting a repair manual or guide can provide valuable step-by-step instructions to ensure a successful repair.

Safety Precautions Overview

Ensuring safety while working on your brakes starts with gathering the right tools and following essential precautions. Before you begin, understand that brake pad materials can vary, so handle them carefully to avoid dust or debris. Always wear gloves and eye protection to prevent contact with brake dust or rotor shards, especially if your rotor design involves intricate parts. Use proper lifting techniques when jacking up your vehicle, and secure it with jack stands. Be mindful of hot components, as rotors heat up quickly during driving and can cause burns. Keep your workspace clean and organized to prevent accidents. Remember, a quick brake fix isn’t worth risking injury—stay alert, follow safety tips, and guarantee your tools are in good condition for a safe, effective repair. Additionally, being aware of proper disposal practices can help prevent environmental contamination from brake dust and debris. Incorporating connected safety devices can further enhance your protection during repairs and ensure a safer working environment. Always stay informed about modern safety technology to optimize your safety measures during vehicle maintenance. Being familiar with standard safety protocols can also significantly reduce the risk of accidents or injuries during your repair process. Furthermore, understanding the importance of environmental considerations can help you minimize your ecological footprint while performing maintenance.

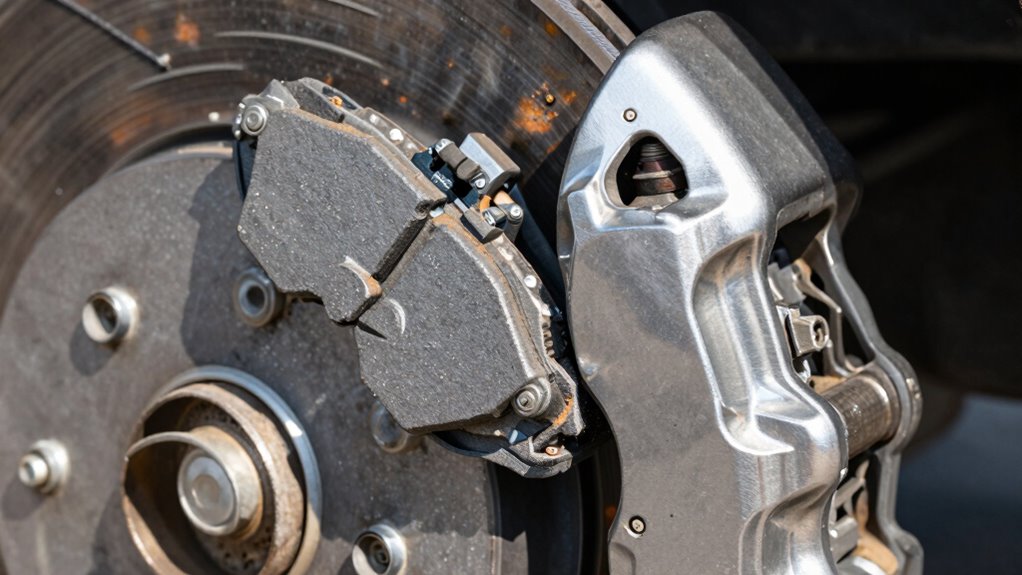

Inspect and Clean Brake Pads, Rotors, and Calipers

To prevent brake rub issues, you need to inspect your brake pads, rotors, and calipers carefully. Make sure to check for uneven wear, cracks, or debris that could cause problems. Regular cleaning and proper maintenance will keep your braking system functioning smoothly and eliminate squeaks or rubs. Additionally, ensuring your brake components are properly installed and aligned can help prevent ongoing issues and extend their lifespan. Proper brake system maintenance is essential for reliable performance and safety. Monitoring for wear and tear can also help catch potential problems early before they lead to more costly repairs.

Proper Inspection Techniques

When inspecting brake components, it’s essential to carefully examine the brake pads, rotors, and calipers for signs of wear or damage. Look for uneven pad thickness, scoring, or cracks on the rotors, and check calipers for leaks or sticking. Confirm the rotor alignment is proper, as misalignment can cause brake rub. Verify the brake fluid level and condition, since degraded fluid impacts braking performance. During inspection, consider these key points:

- Check for glazing or uneven wear on brake pads

- Look for rust or grooves on rotors

- Ensure calipers move freely without sticking

- Confirm rotor alignment for smooth braking

- Evaluate the brake fluid condition to ensure optimal performance and to prevent potential system issues

- Additionally, inspecting the brake fluid quality can help identify contamination or moisture that may compromise braking efficiency

Performing these steps helps catch issues early, preventing further damage and ensuring your brake system functions correctly. Proper inspection techniques also include inspecting brake pad wear indicators to identify when replacement is necessary.

Cleaning and Maintenance Tips

Regularly inspecting and cleaning your brake components is essential for peak performance and safety. Start by checking brake pad wear; worn pads can cause squealing and uneven braking. Clean rotors to prevent rotor corrosion, which can lead to brake noise and reduced efficiency. Use a brake cleaner spray on calipers and rotors, avoiding contact with brake pads. Keep an eye on brake pad thickness and look for uneven wear patterns.

| Step | Tip |

|---|---|

| Inspect brake pads | Replace if thickness is below recommended |

| Clean rotors | Use brake cleaner to remove rust and debris |

| Check calipers | Ensure pistons move freely and are free of grime |

| Monitor rotor corrosion | Remove surface rust with a wire brush |

Perform the 7-Minute Step-by-Step Brake Fix

If your brake system is squeaking or rubbing constantly, you can often fix it quickly with a simple 7-minute procedure. First, lift your vehicle and remove the wheel to access the brake components. Check for uneven brake pad wear, which can cause misalignment, and inspect the rotor for corrosion or rust buildup. Sometimes, rust on the rotor surface causes brake rub. To fix this, lightly sand the rotor with fine-grit sandpaper or use a brake cleaner to remove debris. Ensure the brake pads are properly aligned and free of debris. Adjust or replace worn brake pads if necessary. This quick fix can restore smooth braking and eliminate noise, saving you time and money on more extensive repairs.

- Inspect brake pad wear and rotor surface condition

- Clean rotor and brake components thoroughly

- Realign or adjust brake pads as needed

- Test drive to confirm the fix

Avoid Common Mistakes When Fixing Your Brakes

Before you start adjusting or replacing brake components, it’s easy to make mistakes that could worsen the problem or cause safety issues. One common mistake is neglecting to check your brake fluid level and quality. Low or contaminated brake fluid can impair braking performance, making pad replacement less effective. Avoid rushing the process; rushing can lead to improper installation or misalignment of brake components, which can cause persistent rubbing. Make sure you follow the correct procedures for pad replacement, ensuring all parts are clean and properly seated. Also, don’t forget to bleed the brake system if needed, to prevent air from compromising braking power. Taking your time and paying attention to detail helps prevent common errors and ensures a safe, lasting fix.

Signs Your Brake Rubbing Fix Was Successful and When to Seek Help

When your brake rubbing issue has been addressed, you’ll notice certain signs that confirm the fix was successful. First, the brake pad material should no longer produce squealing or grinding sounds during braking. You’ll also feel a smooth, consistent pedal feel with no vibrations or pulling to one side. Additionally, check that the caliper piston maintenance was effective; the piston should move freely without sticking or uneven wear. Finally, after driving, inspect the rotor and brake components for any signs of uneven wear or residual debris. If these signs are present, your fix is working. However, seek help immediately if you notice persistent noise, increased stopping distance, or uneven brake pad wear, indicating a deeper issue.

Tips to Keep Your Brakes Quiet and Smooth for the Long Run

Maintaining quiet and smooth brakes over time requires regular care and mindful driving habits. Choosing the right brake pad materials, like ceramic or semi-metallic pads, reduces noise and wear. Pay attention to rotor design; smooth, vented rotors dissipate heat better and minimize vibrations. Consistently inspect your brake components for uneven wear. Gentle braking and avoiding aggressive stops also help preserve your brake system’s health.

| Brake Pad Materials | Rotor Design | Impact |

|---|---|---|

| Ceramic | Vented | Quieter, longer lifespan |

| Semi-metallic | Slotted | Better heat dissipation |

| Organic | Drilled | Reduces noise and vibration |

| High-performance | Plain | Easier to maintain |

Frequently Asked Questions

Can Brake Squeal Happen Without Brake Pad Wear?

Yes, brake squeal can happen without pad wear. It often occurs due to vibrations between the brake pad and rotor, which aren’t necessarily caused by worn pads. Factors like dirty or glazed pads, loose components, or moisture can also lead to brake squeal. So, even if your pads look fine and aren’t worn, you might still experience squealing. Regular checks can help identify the root cause and prevent ongoing noise.

Will Fixing Brake Rub Affect My Brake System’s Longevity?

Fixing brake rub is like giving your car a health check-up, and it generally helps your brake system last longer if done correctly. When you perform a brake pad inspection and consider rotor resurfacing, you reduce uneven wear and prevent future issues. Properly addressing brake rub can extend your brakes’ longevity, ensuring peak performance and safety, without causing unnecessary damage or premature failure.

Is a 7-Minute Fix Suitable for All Vehicle Types?

A 7-minute fix isn’t suitable for all vehicle types because brake pad materials and rotor design vary widely. Some vehicles with sensitive or specialized components may require more careful adjustments. Always check your vehicle’s specifications and consult your owner’s manual before attempting quick fixes. For best results, consider professional inspection to guarantee your brake system functions safely without compromising rotor design or brake pad materials.

How Often Should I Repeat This Brake Fix?

You should repeat this brake fix only if you notice the brake rub returning or if your brake maintenance schedule suggests it. Typically, repair frequency depends on driving habits and vehicle type, but it’s wise to check your brakes regularly. If the issue persists after the initial fix, perform the repair again. Always monitor brake performance and consult your vehicle’s manual for recommended maintenance intervals to keep your brakes in ideal condition.

Are There Any Risks of Damaging My Brakes During This Quick Fix?

Think of fixing your brake rub like walking a tightrope—you can cause damage if you’re not careful. During this quick fix, if you’re not gentle with brake pad alignment, you risk rotor surface damage, which could worsen the problem. To avoid this, follow the instructions carefully and don’t force anything. Repeating the fix too often might also cause more harm. Always inspect your brakes thoroughly afterward to make sure they’re safe.

Conclusion

By following this quick 7-minute fix, you can say goodbye to annoying brake squeal and rubbing. Regular maintenance helps extend your brake lifespan and keeps your ride smooth. Did you know that properly maintained brakes can improve stopping power by up to 20%? So, don’t ignore those squeaks—tackle the problem early, and enjoy quiet, safe driving for miles to come. Your car—and your ears—will thank you!